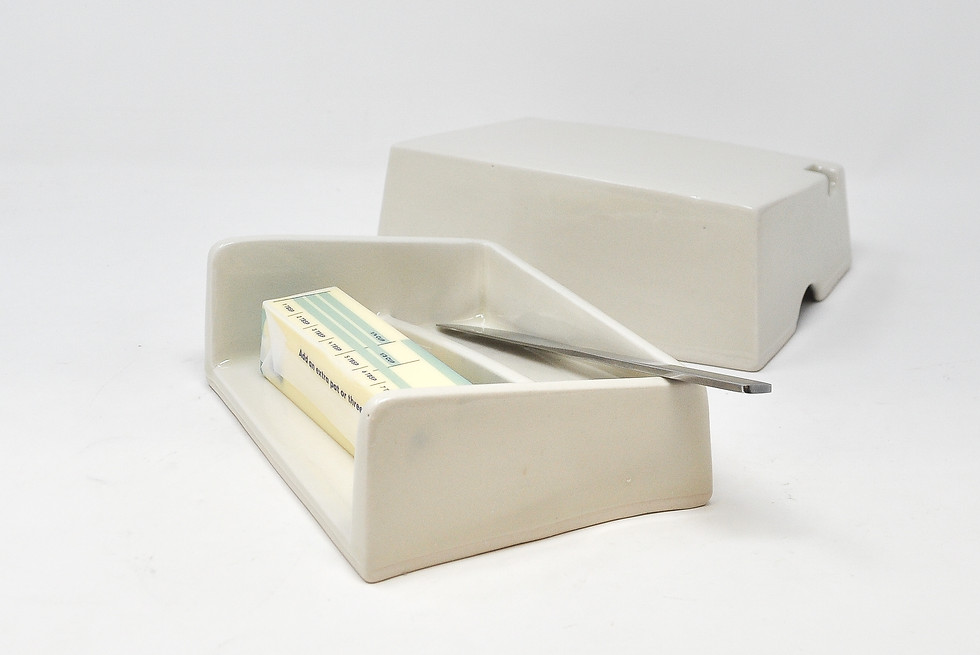

BUTTER BOX

"Domestic amendment: improve an object while taking advantage of ceramic materiality, formal concerns, and use-potentials"

This is a butter dish meant for keeping butter safe from the elements and providing a designated spot for your butter knife.

Sketching and prototyping

Ideating different ways to keep butter covered and integrate a designated place for a knife or butter spreader to be held. There was also originally ideation for a specific butter spreader for this butter holder, but I later decided to cater it to a traditional butter knife.

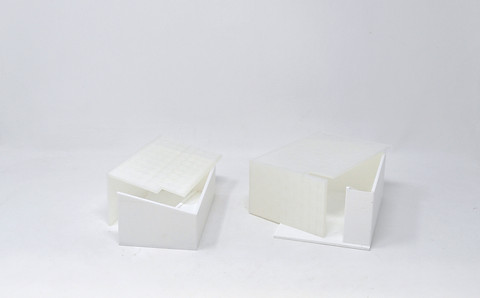

Production models

finalized production models, 11% larger to accommodate shrinkage, includes draft angles, and reservoir attached at the bottom. These were used to make the plaster molds for slip casting.

Mold making

Filling and sanding 3D prints, casting plaster molds, and removing prints from the molds.

Production molds

Two molds, one for the bottom and one for the top of the butter holder. Both one-part molds.

Casting

Pouring slip into the molds, letting it dry for a period of time, pouring the slip out, and letting the remaining clay dry in the mold until it's ready to be removed

Finished butter boxes

I tried out a couple of different iterations done after molding had finished, including taking different walls off the lid, different styles of holes for the butter knife, and some options for handle cut-outs.